Do you worry about the safety of an airplane before taking it to the skies? Rest assured, aside from regularly scheduled maintenance and repair, every flight is preceded by a thorough examination. A preflight check is administered by the pilot and includes an exterior walkaround and visual inspection of the critical parts of an aircraft as well as the cabin. Whether you’re a traveler or an airplane aficionado conquering the skies one adventure at a time, knowing which items are inspected may help put your mind at ease before your next flight.

Determining airworthiness is the responsibility of the pilot, flight crew, and maintenance staff. It is the pilot in command’s duty to perform a preflight check. The maintenance staff is responsible for managing the state and equipment of the aircraft and delivering that information to the flight crew.

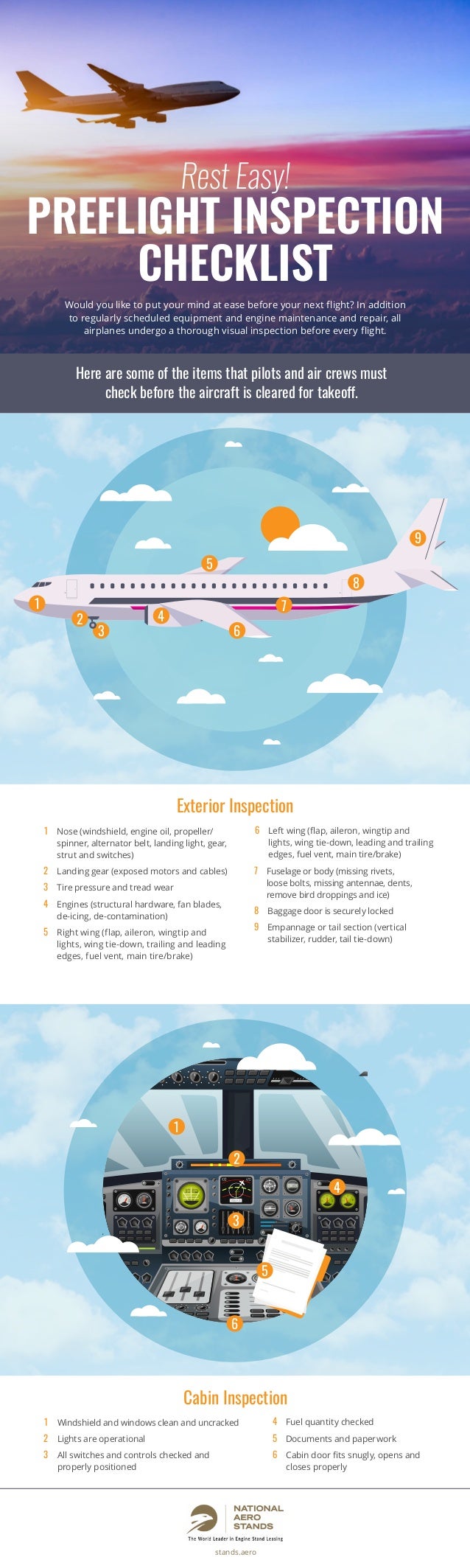

Preflight Airplane Inspection:

Interior Examination:

A good preflight examination includes an inspection of many components. Pilots use written checklists for both takeoff and landing. The preflight inspection usually begins in the cockpit, where pilots check to see if any breakers have tripped, the electrical system is operating normally, and the GPS systems are receiving a signal. These other items are thoroughly inspected in the cockpit and cabin:

• Fuel quantity

• Documents, logbooks, and paperwork

• Lights are operational

• Cabin door fits securely and opens and closes properly

Exterior Inspection:

Outside the aircraft, another inspection is conducted. Pilots check for the freedom of movement of flight controls such as the rudder and ailerons. The jet is also examined for damage that may have been undetected from previous flights such as ground vehicles running into the airplane as well as for fuel, oil, hydraulic, and brake fluid leaks. These additional items are checked to see if they are in proper working order:

• Pilot tubes and static system: Ports and vents

• Nose: Propeller, spinner, alternator belt, windshield, damage from bird strike

• Landing gear: Exposed cables and motors; tires properly inflated and examined for cuts, bulges or irregularities

• Engines: Oil pressure and temperature, fan blades, structural hardware, de-contamination and de-icing

• Right and left wings: Flaps, wingtips, lights, leading and trailing edges, fuel vents, main tires, and brakes

• Tail section or empennage: Vertical stabilizer, tail tie-down

• Fuselage or body: Missing panels, rivets and antennae, loose bolts

When finally cleared for takeoff, pilots will ensure that the lights are turned on and the transponder is transmitting altitude and identification information to radar ground stations. Additionally, engine instruments are monitored upon the takeoff roll. If any abnormalities are detected, the takeoff may be aborted.

Before-Landing Checklist:

A before-landing examination is also conducted before the pilot leaves cruise altitude. Final items are inspected once the landing gear, propeller, and flaps are positioned for landing.

• Cowl flaps

• Fuel selector

• Directional gyro

• Seat belts and shoulder harnesses

A thorough preflight aircraft inspection takes time but is crucial in ensuring proper operation, safety, and the prevention of accidents. To learn more about how pilots tend to an airplane’s mechanical well-being, see the accompanying preflight inspection checklist.

Courtesy of National Aero Stands

Read Also: